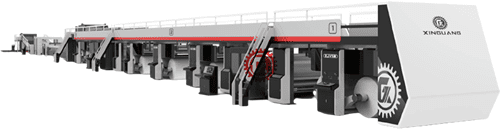

GM40Gluing Machine apply glue evenly in high speed running

Gluing machine GM40 is designed for highest speed production line in China

GM40 gluing machine working width is from 2200-3300mm, and no production line width is bigger than 3300mm in the world. The GM40 gluing machine is just designed and made for the biggest size production line, and its design speed is 350m/minute, this is also the highest design speed corrugated carton production line in China

So whatever aspect we consider, GM40 gluing machine stands for the highest technical level machine in corrugated carton machine manufacture industry.

Structure of GM40 gluing machine

The GM40 gluing machine has single layer for 3 layer production line, 2 layer for 5 layer production line and 3 layer for 7 layer production line. Its glue applying roller diameter is 320mm, glue uniformity roller diameter is 215mm, each layer is drove separately by servo motor, the gap between rollers is adjusted by PLC. The frame structure is made by casting iron, it can make sure the machine working stable, with diameter 400mm pre heater to make the glue melt fast, two pressure roller for glue applying evenly. With a stainless glue channel, circulate offer glue automatically.

Glue for gluing machine

Most of corrugated carton machine adopt starch glue for corrugated cardboard production. The gluing making station is just for making glue for the corrugated cardboard production line.

Every time, after sale production line, we will arrange 1-2 engineer to customers site for installation and training workers, on the time, my engineer will teach customer how to make glue. We have a formula method for making glue, then after preparing all material for making glue, we can start to produce glue.

It is a simple process, easy to study, and our engineer will adjust the formula of making glue as per the weather, moisture, paper quality.