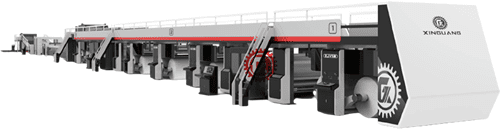

Double Facer SM12 Is Wet Part of Corrugated Paperboard Production Line

Double facer is one of wet part of the corrugated paperboard production line

As we know, the corrugated paperboard is combined by wet part and dry part. The wet part is for corrugated cardboard laminating and making papers to be difference layers of corrugated cardboard. It will work with steam or heating parts.

The double facer is the biggest machine in wet part of the corrugated cardboard. It has big size roller for driving, heating part which is heated by steam or other heating method, and cooling section to finalize the corrugated cardboard smart and strong.

When the production line running, we can see lots of steam around the double facer.

Structure of double facer SM12

This is economic model of double facer, its speed is 120m/minute, and it is designed for our economic model of corrugated paperboard production line in speed 120m/minute. The main difference between SM12 double facer and other double facer is the heating plate size is difference.

SM12 double facer heating plate is 600mm, but other model double facer, their heating plate is 700mm.

On the two end of the double facer, there are 2 pairs of rollers, one pair of roller is drive roller, it will pull the cotton belt moving, the other pair of roller is not with drive. The cotton belt is fixed on the two pairs rollers, when the drive roller run, then the cotton belt will run too, and take the corrugated cardboard move on the heating plate, to finish the corrugated cardboard final process for its strong and quality.

Difference moddle of SM12

SM12 double facer we also have two models for it. One is SM12-9, it means the double facer with 9 pieces of heating plate, this is only for 3 layer production line, because 9 pieces of heating plate is enough to make sure the 3 layer production line runs in speed 120m/minute.

The other model is SM12-12, it means the double facer with 12 pieces of heating plate, this is for 5 layer production line, also for 7 layer production line, it is also adopted. when we want to produce 5 layer and 7 layer corrugated paperboard, we need more heating plate to make sure the corrugated cardboard quality.