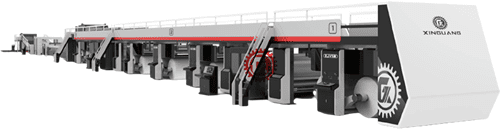

SM35 Double Facer With Difference Quantity of Heating Plate

Position of double facer in corrugated cardboard production line

In corrugated cardboard production line, there are lots of difference machines in difference position for difference function. The position of each machine is decided by what function it is for. Double facer is for baking and drying glue to finish multi ply corrugated cardboard sticking, and it has a cool section for finalized the multiply corrugated cardboard. Then before the double facer, it is gluing machine, gluing machine applies glue on 2 ply corrugated cardboard and paper, then they will be laminated in double facer for baking and dry. After the double facer is Slitter Scorer, after cooling section, the corrugated cardboard is ready, after that we will cut the corrugated cardboard in sizes which we need. We can know that the double facer is the final process for complete corrugated cardboard laminating to 3 layer, 5 layer and 7 layer corrugated cardboard., after that, the corrugated cardboard will be cut.

Pressure of double facer to corrugated cardboard is important

When the corrugated cardboard pass double facer, the double facer will give pressure on the corrugated cardboard for laminating, and the pressure is very important for corrugated cardboard quality.

If the capacity of pressure is too big, the flute of corrugated cardboard will be collapse. If the pressure capacity is too small, the laminating will be fails, because each layer can not be stick well. For difference quality paper, when we producing corrugated cardboard, we need to adjust the pressure capacity as per difference paper quality.

What we need to concern on old double facer

After long years working, old double facer maybe with some problems.Due to the long-term uneven wear of the corrugated cardboard on the hot plates during corrugated cardboard producing, the heating plate surface concave maybe more and more serious.it will not only reduces the thermal conductivity efficiency of the double facer due to the lack of contact between the corrugated cardboard and the hot plate surface, but also causes significant waste of thermal energy, at same time, the corrugated cardboard cannot be bonded without pressure, while the cardboard in the middle may break or invert flute due to overload, resulting in a large amount of waste of corrugated cardboard and economic losses.

Then we need to check the double facer condition, and changing heating plate on time, or buy a new double facer to be instead of old machine.