SM30 Double Facer is the key part for the quality the corrugated cardboard

Function of SM30 Double Facer

This model of double facer design speed is 300m/minute, working speed normally is 180-300m/minute, for high speed running machine, it can only adopt steam heating, and its requested temperature is 160-200℃

Double facer is used to stick the 2 ply or 4 ply corrugated cardboard with a facial paper, it likes a laminator, the corrugated cardboard will be finished by heating and pressing in the double facer.

SM30 double facer has some pieces of hot plate in size 750mm. The surface of the hot plate is treatment by grinding, then it is cooling section in length 5m. The hot plate is a pressure container with pressure certificate, the steam will be in the hot plate, so the pressure certificate is essential.

The double facer has multi sections for temperature control with a temperature display.

The double facer has a big size cotton belt, the driving roller will take the cotton belt running, then the belt take the corrugated cardboard moving on the hot plate. The upper belt is web automatically. The lower belt adopts pneumatic tensioning mechanism, the structure is simple and practical, the left and right of the lower conveyor belt is automatically corrected and aligned, and it can also be adjusted manually on both sides.

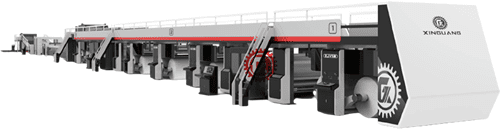

Beautiful design of SM30 Double Facer

The SM30 double facer with a beautiful design for its appearance. There are shells to pack around the machine, we will not see the mechanical system directly, instead of this, the double facer with nice design doors, also it can prevent worker to be too closed to the machine to make srue workers safe.

Bigger size than lower speed machine

Because high speed design, then it need more hot plates to dry the corrugated cardboard. so the length of SM30 double facer is longer than other lower speed machine. Whatever the double facer for 3 layer production line or 5 layer production line, SM30 has more hot plate than other lower speed double facer. In theory, more hot plates can support higher speed running.