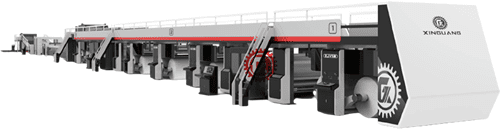

SM20 Double Facer for The Middle Speed Production Line

Double Facer SM20 design speed 200m/minute

This model double facer is very popular because it is designed for the corrugated carton production line in speed 200m/minute. The most popular model of corrugated carton production line is in speed 200m/minute.

From this model to the higher models, our design for the double facer is with safety doors, it has a more beautiful appearance and more safe than SM120 double facer.

For make sure its running stable in the speed 200m/minute, the SM20 double facer is heavy model than SM120 double facer.

Difference model of SM20

From this model double facer to the higher models, the heating size is 750mm to be instead of 600mm.

Sure for difference layer corrugated carton machine, this model double facer also in difference models again. One is SM20-8, this means SM20 double facer with 8 pieces of heating plate, it is with fewer heating plate because it is enough for 3 layer corrugated carton production line working in 200m/minute. And for 5 layer corrugated carton line, the model of double facer is SM20-13. It is easy to understand what it means, it means SM20 double facer with 13 pieces of heating plate, it has more heating plate for 5 layer production line works in speed 200m/minute.

Heating plate is most important parts for double facer to finish the final process of corrugated carton quality

As we know, heating plate is very important, its quantity is as per the production line running speed. That means when the production line runs, the corrugated cartons will pass on the surface of the heating plate in high speed. Then we need special treatment on the surface of heating plate. It will be fine grind carefully. And the steam is inside of the heating plate, then for safe consideration, it should be with pressure vessel certificate.